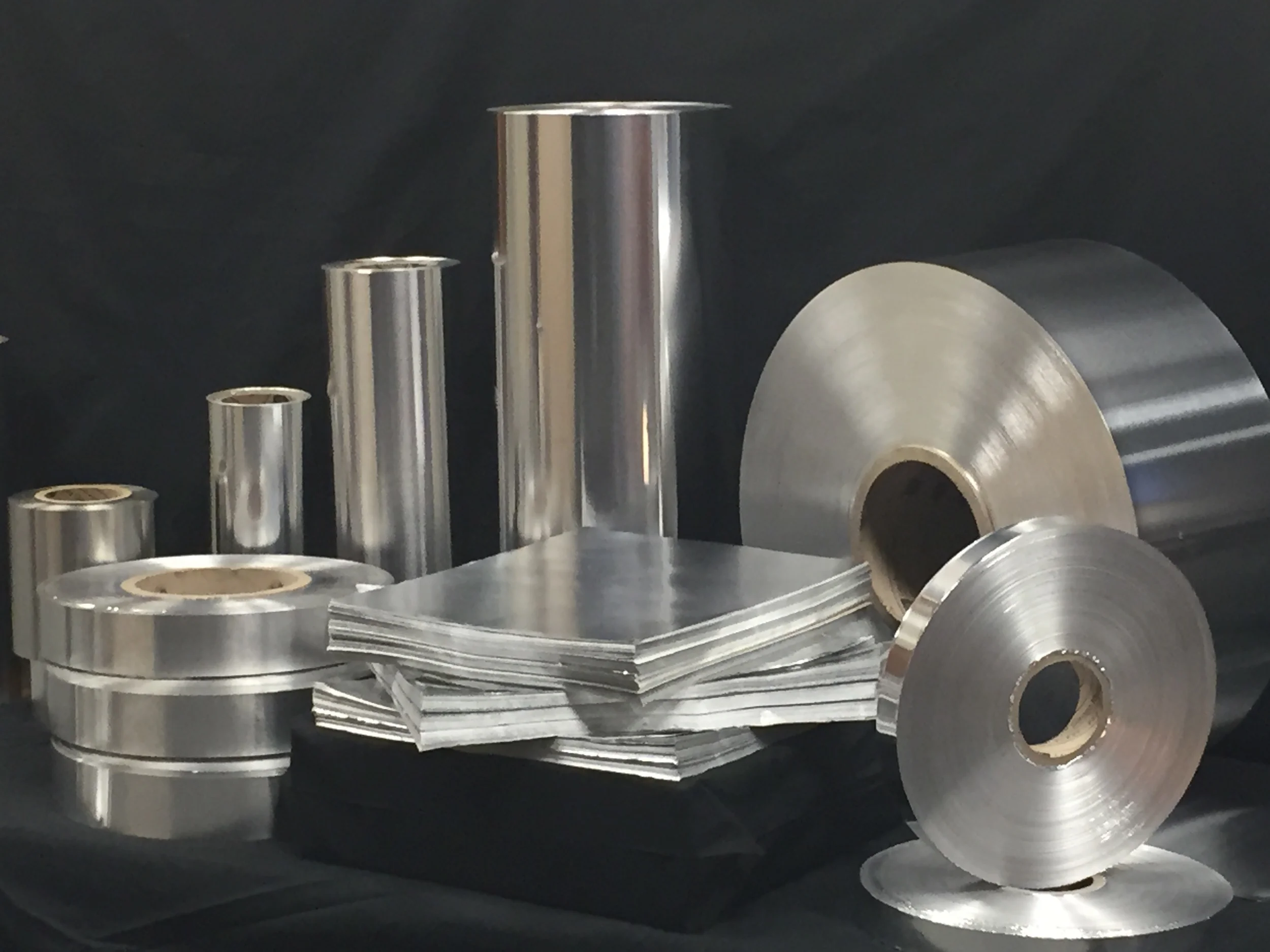

Aluminum

Since the extraction of aluminum from ore back in 1825, the applications and uses for this one of a kind metal have exponentially grown. Throughout history, aluminum has been utilized in virtually every era, especially in the early 1900's, through WWII, and continuing into present day

Characteristics

Aluminum has many desirable characteristics for a metal that makes it possible to have a broad range of applications, such as:

Unaffected by sunlight

Light weight

Hygienic

Pliable

Non-toxic

Non absorptive

Heat Reflective

Efficient moisture barrier

Alloys & tempers

Common Alloys: 1145 (99.45% aluminum), 1235 (99.35% aluminum), 1100 (99.0% aluminum)

Specialty Alloys: 3003 (widely used as a general purpose alloy for moderate-strength applications requiring good workability) 5052 (moderate to high strength, good resistance to corrosion)

Dead Soft - also known as "fully annealed"; foil is given an extra pass in the oven to become as dry as possible or oil free while still considered to be easily unwound. Annealed metal is brought to a specified temp and cooled slowly to achieve an oil free finish.

Full Hard - a foil that retains its rolling oil on its surface and is completely hardened.

LGM Advantage

Stock an extensive range of aluminum gauges, alloys and widths.

Gauge: Aluminum stock up to 0.020".

Alloy: 1XXX series alloy, 3003 plus more specialized alloys upon request.

Specialize in Wide Width availability: Process capability up to 83" and stock up to 72"

Customer specific stocking programs save you time and money.

WE ARE COMMITTED TO EXCEEDING YOUR EXPECTATIONS